Bread production may be divided into these stages:

• dough making and kneading

• dough dividing and forming

• baking

The more water obtains the dough the more delicate the bread will be

and the longer it will stay fresh. The process is long and costly but it

helps to produce an absolutely natural product.Such equipment allows to make dough in a closed way which is rare for Russian bakeries.This process is fully automated and lasts at least 14 hours.

Ready dough is poured into a big portable bowl.

In accordance with the recipe they add required ingredients to it.

Weight of the added ingredients is checked with accuracy up to 1 gram.

Then the bowl is put under the dough mixer. The cover has a hole through which some more components may be added while mixing. Proper mixing is an essential condition of the pastry beauty after baking. The crust beauty depends on the amount of sugar and starch.

Then the dough should stand for 14-28 hours at low temperature to gain proper smell and taste.

This convection steamer makes filling for the pastry.

Speedy mixer for the dough and filling

From right to left: dough making equipment, machines for weighing and adding components to the dough, mixing and beating machines.

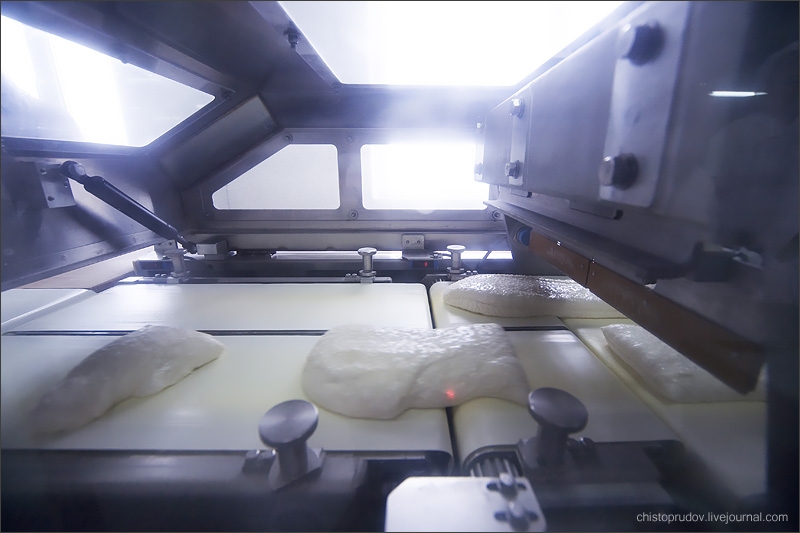

Equipment for dividing dough – a unique Japanese machine.

It can work with the dough 85% wet that cannot be held with hands.

Conveyor. Laser helps to control the length of a half-finished product.

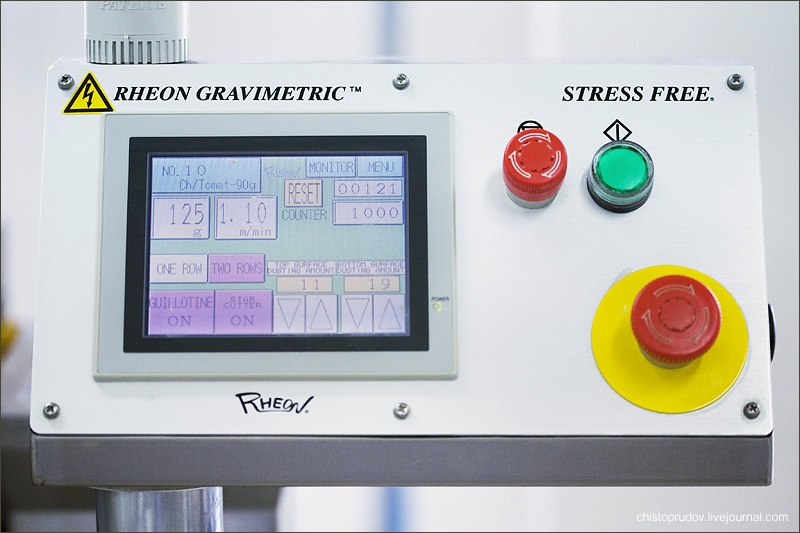

All parameters of cutting are adjusted through such control unit.

The machine controls the shape and weight of the piece.

Fingers should be kept away

This line of the production is called “divider-rounder”.

It’s used for harder dough.

The bowl is put on a special lifting device.

The dough fills the machine up.

The divider. An operator adjusts the weight of the pieces…

… and checks them on electronic scales. The workpieces weigh about 10% more than ready products due to the water that evaporates.

Some dough is simply divided to pieces, other is turned into cylinders.

They use various edible coatings.

Baguette line

Baguette workpieces

Tape measure helps to control their length.

Putting on the baking tray.

Or the dough may be put in special capacities for storing.

Or it can be put on the oven loader.

After being divided the dough has to lie for some time.

The dough is growing due to dampness and yeast.

Shaping

Making cuts

Being washed over

And then baked

In a rotary oven

Or in a hearth oven, such ovens are used for baking big rye-wheat or wheat products.

Natural stone is used as a hearth.

The heat is produced not in a convection type but a radial one.

It’s a spare regime that doesn’t dry the air much.

The crumb is more delicate in result.

The hearth is vacuumed after each baking.

Prepacking

Excess flour is removed

Ready products are put in boxes and are never wrapped in polyethylene packages because polyethylene doesn’t let bread breathe though prolonges its freshness…

Empty boxes return from stores

They are placed to wait for fresh bread.

At such production they get absolutely natural product with unique appearance and exclusive taste. Its disadvantage is high cost compared to the one of ordinary bread.

Source ; englishrussia.com

Aucun commentaire:

Enregistrer un commentaire