What fabric is used for making uniforms

worn by workers of administrative departments, railway companies and by

schoolchildren? How woolens are made? To get answers to these questions

we are at the Bryansk worsted factory.

Worsted is rather different from woolen

fabrics. They are made from long wool subjected to combing. Worsted is

thinner than woolen fabrics and it’s not fluffy. The material is smooth

or a bit fleecy, it can be purely made from wool, be half woolen (when

cotton yarn is also used) or mixed when other fabrics are also added.

Worsted production starts from raw materials preparation. It comes to the factory in such sacks.

The wool in the sacks is already clean.

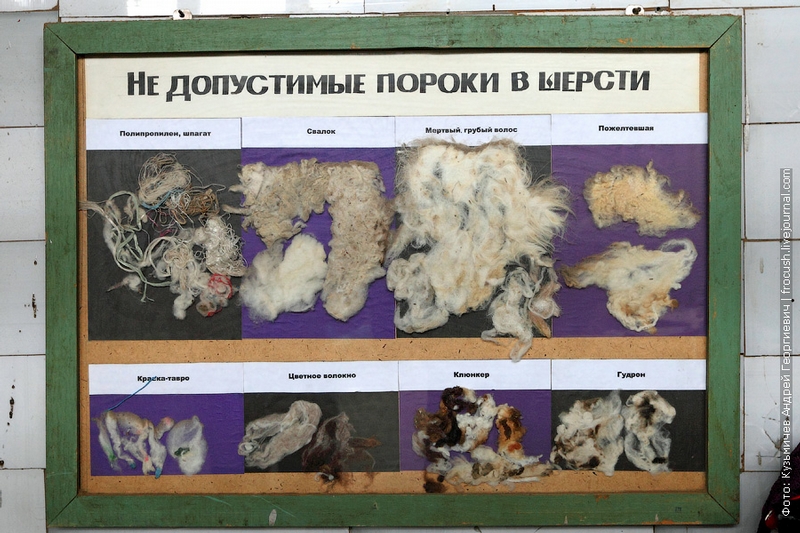

The wool must be manually sorted out. Defectшму wool should not enter the production process.

These are the samples of defective wool.

This is how a future suit looks like!

This is a blowroom machine.

As far as we are watching the process of

making half woolens we need not only wool, but also man-made fiber.

Lavsan, for example. It is loaded in another blowroom machine.

Now the wool is to be combed by a special machine. The fibers shorter than five cantimeters and impurities are to be eliminated.

Combing process.

Ready!

The combing process is perfomed in two stages. This is the second one.

They need to maintain special

conditions: air humidity should be 75-90% so they use special sprinklers

hanging under the ceiling.

The second stage of combing is over.

Ready products.

Now they check the products again and remove any impurities, make the fabric more dense.

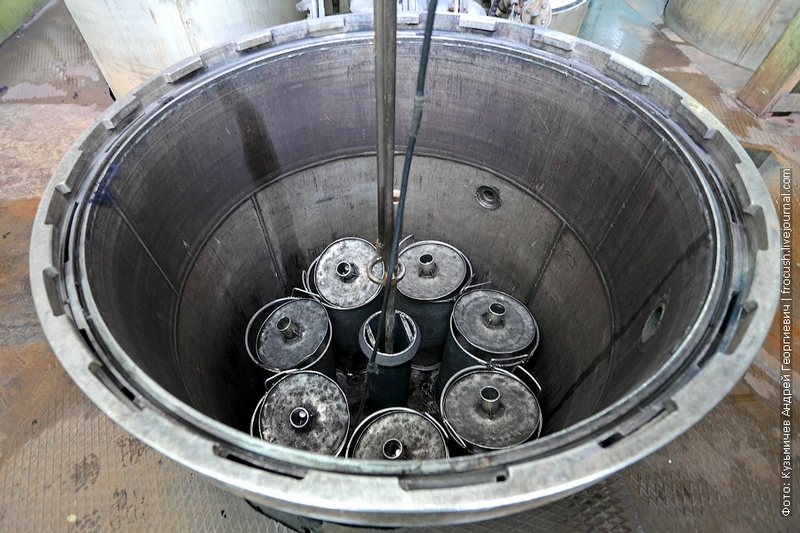

Now the fabric is put in circles into the big cylindrical containers.

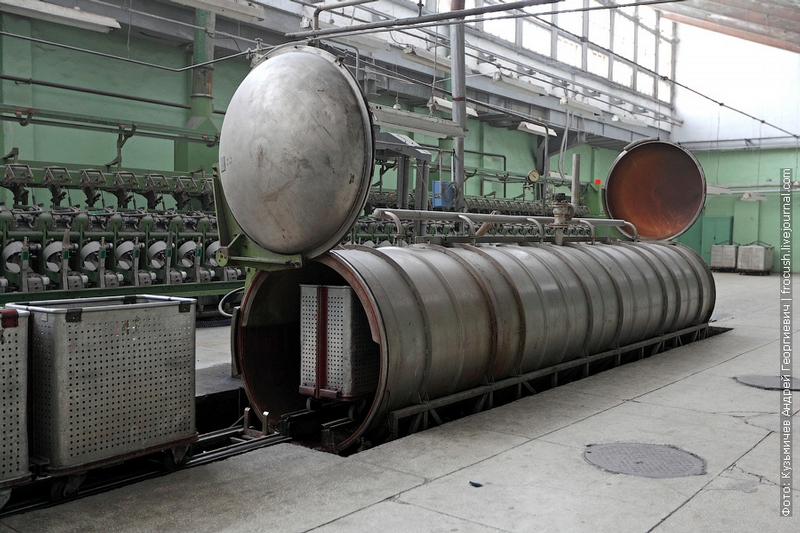

To make wool of different colors they use special dye. They dye the wool (or man-made fiber), wash and dry it.

Between two shops.

“Dying”.

Dyed woolen and acrylic fibers come to

the roving frame where they are combed again and turned into even more

dense band (foreyarn). It’s the very stage where woolen and acrylic

fibers meet.

These ones are ready for spinning.

Here woolen thread is born.

These are the spools with wool yarn.

The rereeling machine rereels the wool from spools to bobbins.

Empty spools.

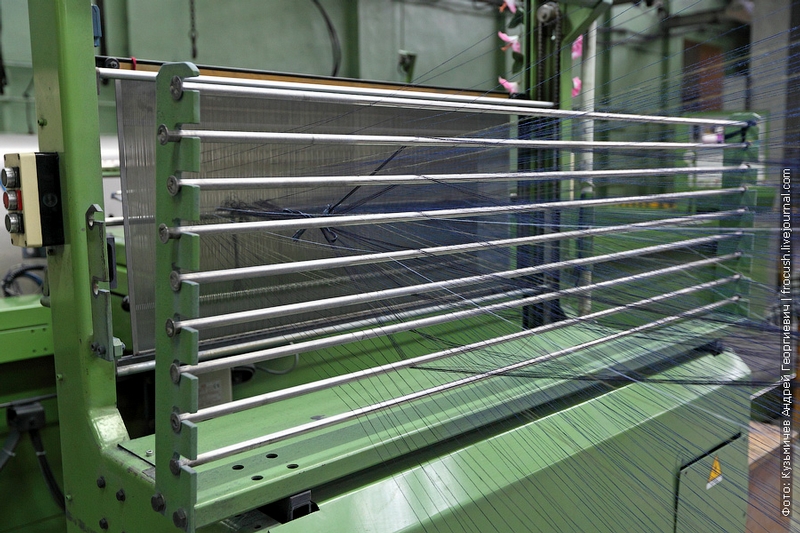

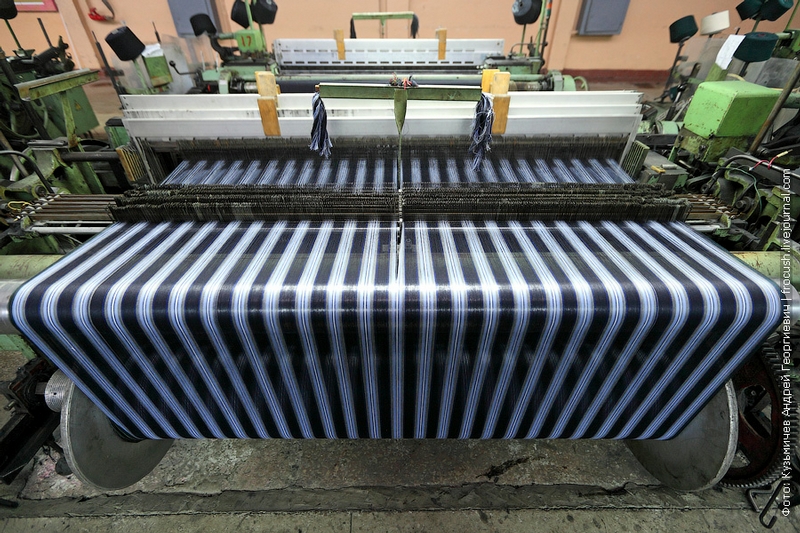

The warping machine.

The looms.

The air should be humidified.

This section is for dying, drying, decoration etc.

The electric lift moves along these rails.

Though some remote parts of the shops can look like this…

Checking the quality of the products.

The canteen at the factory.

The Bryansk worsted factory makes fabric for uniforms worn at various Russian ministries.

School uniform.

Uniform worn by employees of “Russian Railways” company.

Leaving.

Thanks for the excursion!

Source ; www.englishrussia.com

Aucun commentaire:

Enregistrer un commentaire